Creality K2 Plus Review: Now in Color

The day has finally arrived for Creality’s entry into color FDM printing, and it’s been worth the wait. After a rather disastrous 2023 foray into speedy core XY machines – the K1 suffered from poor build quality – the team took their time working on the K2 Plus Combo. The results are a delightful, fully enclosed Core XY machine with a monster 350x350mm build plate that overshadows anything from the competition.

The most notable feature is a heated chamber that comes in handy when printing engineering filaments like ABS and nylon. It uses a Creality fork of Klipper, has tons of sensors for excellent bed leveling, and comes with two AI-driven cameras for monitoring prints. We were invited to test out the “combo” unit, which includes a four-color CFS (Creality Filament System).

The K2 Plus Combo could be called a clone of the Bambu Lab X1C. It is, but with some better features and others a bit worse. On the plus side, well, it’s PLUS. The 350 x 350 x 350mm is significantly larger than the X1C or P1S, which both weigh in at 256 x 256mm. On the negative side, Creality used a significantly larger high-flow nozzle, which wastes more filament between color swaps, and the heated build plate needs a good 15 minutes to warm up before printing.

It retails for $1,499 with the four-color filament unit and could also be purchased on your own for $1,299. We’re impressed by the overall capabilities of the Creality K2 Plus and consider it one of the best 3D printers you can buy.

Specifications: Creality K2 Plus

| Build Volume | 350 x 350 x 350 mm (13.78 x 13.78 x 13.78 in) |

| Material | PLA/PETG/TPU/ABS (up to 300 degrees) |

| Extruder Type | Direct drive |

| Nozzle | .4mm (Unicorn) |

| Build Platform | Coated steel flex plate, heated |

| Bed Leveling | Automatic |

| Filament Runout Sensor | Yes |

| Connectivity | LAN, Creality Cloud, USB Flash Disk |

| Interface | 4.3 inch Color touch screen |

| Machine Footprint | 495 x 515 x 640 mm (19.4 x 20.2 x 25in) |

| Machine Weight | 35 KG (77.16 lbs) |

Creality K2 Plus: Included in the Box

The Creality K2 Plus comes with everything you need to get your printer set up. You get tools to maintain the printer, side cutters, a plastic scraper, and a USB stick. There’s also a sample spool of white Creality Hyper PLA to start your printing journey.

You also get a PDF copy of the manual, a copy of Creality Slicer and sample models in both pre-sliced .gcode and .stl format. There’s also a very helpful video to help you operate your machine.

Design of the Creality K2 Plus

The Creality K2 Plus is a modern looking, fully-enclosed Core XY printer, similar in appearance to the K1C, with a space age Creality delta logo on the side. It feels like a good quality build with a die case aluminum alloy frame, a glass door and removable glass lid.

The build volume on the K2 Plus is 350 x 350 x 350mm, which is, oddly enough, bigger than the K1 Max’s 300 x 300 x 300mm. Does this mean an even bigger color machine is in the works? No idea, we’ll surely find out later this year.

The flex plate is a textured PEI coated sheet that sticks to a magnet covered 5mm aluminum heat bed. One nasty flaw I found is the bed needs to really soak up a lot of heat before you get a good first layer – something I didn’t notice on smaller prints, but can really mess up a larger print. Creality may be able to address this in a future firmware update, though I’m not sure how. It’s one of the oddest flaws I’ve run into, and I’m worried it will trip up a lot of new users.

The K2 Plus has a sturdy, thick glass lid that is strong enough to support the weight of the CFS. This is good because the lid is the only place you can put the CFS. The cords that came with the printer are too short to put the CFS on the table next to it. Hopefully, Creality will fix this oversight, as the machine is shown on their website with four CFS units on the side.

The cord issue makes maintenance more troublesome as you can not remove the lid without first turning off the machine and unplugging the CFS, which can not be unplugged while powered. When I got a clog – due to testing PLA with the door closed – I resorted to bending a piece of piano wire from the craft stash to fit in the tight space rather than dismantling the entire machine.

Speaking of running the machine with the door closed – don’t. Not unless you’re using high temperature filament like ABS or nylon. The machine has extra cooling, an exhaust fan, plus a temperature gauge to let you know how warm the chamber is getting. The default chamber temperature for PLA and other cool materials is 35 ℃, which may be too warm for some filaments for periods of extremely long use. I tried to push it to cool the chamber to 30C, and it couldn’t reach that without opening the door.

If you want to run ABS or Nylon, the toasty interior becomes a positive feature. The chamber has active heating, allowing it to reach 60 C. This vastly improves the performance of materials like ABS, which love to warp when exposed to the slightest draft.

Creality uses the long “unicorn” style nozzle for the K2 Plus, but it is not compatible with the previous K1 nozzles. The nozzle is a one piece design inspired by E3D’s Revo and likewise prevents leaks that can result from loose nozzles. The nozzle is proprietary but is readily available at Creality’s store and Amazon.

The K2 Plus has a single filament spool you can bolt to the side if you didn’t opt for the CFS or have a spool that doesn’t fit the CFS. There is an RFID tag reader on the side of the machine, so it can still read Creality branded filament.

It has a similar motion system as the K1 series, though it can now hit acceleration rates of 30,000 mm/s². Rubber feet are included, which help dampen vibrations, though it still jiggles like crazy on some fast prints.

It has the same screen and easy to use menu system as the other K1 printers, with helpful thumbnails supplied by Creality Slicer. Because it’s running a variation of Klipper, the K2 Plus remembers everything it has printed until you clear out the memory, which makes it great for running recurring parts.

There are three ways you can send files to the K2 Plus. It can take files from a USB stick, through WiFi over your home or office LAN, and through the Creality Cloud. I’m not a big fan of the Cloud – it’s overly busy and gamified for my tastes – so it’s good to have options.

The K2 Plus also has a preinstalled camera for monitoring your prints and taking timelapse videos. A second AI camera on the tool head is used for flow rate and pressure advance calibration. You’ll need to use Creality Cloud and the mobile app to get print fail warnings from the machine.

The Creality Filament System (CFS) looks a lot like a Bambu Lab Automatic Material System (AMS) and operates largely the same way. I found it much easier to load as there are no stiff buttons to release the feed mechanism tension. It has a similar compartment for desiccate packs to keep filament dry, and a large display on the front of the CFS tells you what the temperature and humidity levels are inside the box. There’s no active heating element, so the temperature fluctuations are only from sitting on a hot printer.

Creality said the CFS would one day be compatible with other printers, such as a v3 series Ender, but the bed slingers would need a modified tool head with the ability to cut filament and new firmware.

Assembling the Creality K2 Plus

The Creality K2 Plus is fully assembled and only needs to be unboxed and unpacked. You’ll need to remove all the packing foam, unscrew three screws holding the build plate on, plug in the touch screen and pop the filters inside the machine.

Leveling the Creality K2 Plus

The Creality K2 Plus has a fully auto leveling program that includes input shaping with the help of built-in sensors. Just push the button and the machine does the rest. It will also recheck the level before each print, and if you’re dialing in new filament, it can do a full calibration at the touch of a button.

Loading Filament on the Creality K2 Plus

The CFS makes loading filament a snap, just drop in the spool and feed the end into the tube. The machine does all the rest. If you’re using Creality filament, it will detect the RFID tag and automatically send the type of filament and color back to your computer and Creality Slicer. If you use a 3rd party filament, you will need to select the type and color of the filament at the printer screen.

Preparing Files / Software for Creality K2 Plus

Creality included a copy of Creality Print 6.0, a custom program that integrates file retrieval from the Creality Cloud with slicer and file delivery. Using the Cloud is completely optional, as you can drag and drop stl files from your hard drive into the slicer and transfer files with LAN or a USB stick.

The interface has a LOT going on, but once you find all the buttons, it’s as good as Bambu or OrcaSlicer. There are presets for just about any filament you need and eight settings for the printer itself, including a Hueforge mode. The “device tab” is a simplified Klipper screen where you can see your printer’s file storage, temperatures, motion system, and camera. To access the full Fluidd screen, you need to type your machine’s IP address followed by 4408.

One problem with Creality Slicer is the lack of control for purge volumes. You can only change the “multiplier” not the individual number. Actually, you CAN change the numbers, but as of this review, it is doesn’t do anything. This is wasteful because you have to set the purge for your lightest filament, which may be overkill for a swap between two dark colors.

Printing on the Creality K2 Plus

The Creality K2 Plus comes with a small sample roll of Hyper PLA, Creality’s high-speed filament, which promises high strength and smooth prints while running at speeds up to 600 mm/s. If you want more colors and materials like silks and multicolor filaments, you should check out our guide to the best filaments for 3D printing for suggestions.

One annoyance I ran into with the K2 Plus is the amount of color waste. Due to the printer’s high-flow nozzle with its exceptionally long melt zone, there’s a ton of filament that needs to be cleared out between color swaps. The slicer suggests a purge of 965mm cubed to go between black and white – that’s about 15 inches of filament!

The color transitions are incredibly clean, and the K2Plus was able to print my test model – a Cinderwing dragon head in three colors – 56 minutes faster than my Bambu Lab P1P. However, the Bambu Lab purged 99 grams of filament using Bambu Studio’s default settings, while Creality Slicer 6.0 needed 121.7 grams. This was for 206 color swaps. The white, which only needed 2.28 grams of filament but was on 75% of the layers, took up 78 grams of waste. The orange and black only required 26 and 17 grams each, so the moral of the story might be…don’t use white.

Note: This is the waste from 206 color swaps, and the model size itself is irrelevant. You can save yourself a lot of wasted filament if you print multiples of the same item – or in this case, the whole dragon.

I ran a Benchy using “speed benchy” rules: .25 layer height, 2 walls, 3 top & bottom layers, 10% infill. I turned off anything that could slow the print speed and cranked the acceleration. I stuck to the default speed of 200/300 mm/s. This is printed in Inland’s gray PLA – an everyday filament that is brutally honest in photos.

The Benchy has a lot of visible layer lines and slightly droopy overhangs but it is otherwise a pretty decent print when you consider it was printed in 15 minutes and 56 seconds. An Ender 3 S1 running at its top speed of 100mm/s would take 55 minutes to print using similar settings.

I ran a lot of models through the K2Plus, but this Three Year anniversary edition of Cinderwing’s Crystal Dragon is my favorite. Printed in EPAX Magic Peacock tricolor silk, with accents in Bambu Lab white silk PLA and Flashforge Sparkle Black, this full sized dragon printed crisp and clean, with smooth layers and no problems remaining stuck to the bed. The tricolor filament did twist a little more than I would have liked, but it’s still a good effect. It printed in 18 hours and 59 minutes, using .2 layer height and mostly default settings. I decreased the outside wall to 60mm/s to get the most shine from the silk filaments. There were 207 grams of waste, plus 17 more grams in the purge tower. The model only weighed in at 205 grams of total PLA.

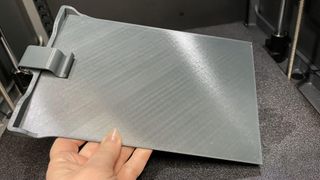

To test out PETG, I printed a mini clipboard in Prusament Anthracite Grey PETG. I let the bed heat soak for 15 minutes to get a good first layer, and I wasn’t disappointed with this nicely smooth surface. I was able to fit two of these 220 x 450 mm boards at the same time, with the clips printed on the edge. It took 3 hours and 16 minutes, with a .2 mm layer line and Creality Slicer’s default PETG settings.

The K2 Plus can’t print TPU with its CFS and didn’t want to use Bambu Lab’s new “TPU for AMS” in there either. This TPU is stiffer and works great in Bambu’s similar filament system. But in the K2 Plus, the material jammed up in the tubing before ever reaching the hotend. So I swapped the TPU to a freestanding spool holder and fed it through the single material entry point. Now, the slicer had issues and refused to acknowledge the external spool color, despite showing it as an option in the color picker. This is an annoying bug that I hope Creality will soon fix.

Despite the hassle with the slicer, the machine ran the TPU beautifully, and I got this rose printed in 55 minutes using a .2mm layer height. The layer lines are practically invisible, and the layer adhesion is very strong.

For ABS I ran a 200% Dummy 13 action figure. I used the “runner” method, where each color is printed attached to a card. This method does waste a little material, but is less likely to have print fails. Each color was printed separately and took about 4 hours and 6 minutes each. I used the designer’s settings, with a .15mm layer height but Creality’s default ABS speeds around 200mm/s. This was printed in Polymaker Red ABS and Cat Yarn ABS Sparkle in Cheshire Purple. I picked up this spool while attending SMRRF in England, so it might be difficult to get in the US, but UK makers should definitely check it out – it’s currently on sale for £18.

Bottom Line

The Creality K2 Plus is an excellent printer for makers who want a fast, four color, super roomy, fully-enclosed Core XY 3D printer. This machine is currently the biggest color machine on the market and has loads of features, including two AI cameras and hands-free leveling.

Creality still left a few bugs to squish, but they all seem to be in the slicer and firmware. Heat soaking the bed cures it’s first layer woes, and the TPU slicer bug should be fixed shortly. The machine itself is solid. It’s also running Open Source Klipper, so if you want to keep your files to yourself and mod the firmware, you’re free to do so.

Retailing for $1,499, the K2 Plus is not cheap, but it is worth it if you need the size. If you want more bang for your buck, there’s always the Bambu Lab P1S, which is $949 when bundled with a 4-color AMS. If you want a bigger single-color printer Core XY, check out the K1 Max, which has similar features but a 300x300mm build plate. It’s currently on sale for $719.

MORE: Best 3D Printers

MORE: Best Budget 3D Printers

MORE: Best Resin 3D Printers

#Creality #Review #Color